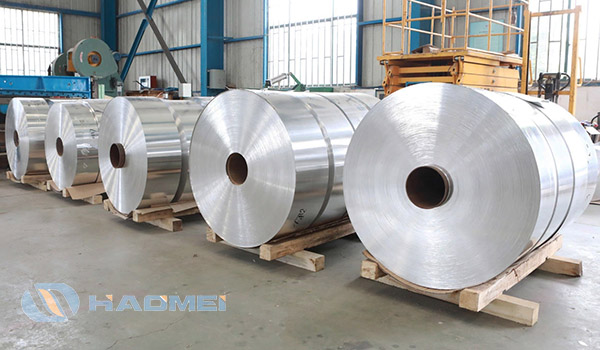

3003 aluminium alloy aluminum coil manufacturers

April 28, 2020

3003 aluminium alloy aluminum is a widely used anti-rust aluminum. Like most other aluminium-manganese alloys, 3003 is a general-purpose alloy with moderate strength, good workability, and good corrosion resistance. It is commonly rolled and extruded, but typically not forged. Its strength is not high(slightly higher than industrial pure aluminum) and it can’t be heat treated, so the cold working method is adopted to improve its mechanical properties. As a wrought alloy, 3003 is not used in casting, and more frequently used to resist moisture in sheet metal applications such as gutters, downspouts, roofing, and siding.

The alloy composition of 3003 aluminium is:

Aluminium: 96.8 to 99%

Copper: 0.05 to 0.20%

Iron: 0.7% max

Manganese: 1.0 to 1.5%

Silicon: 0.6% max

Zinc: 0.1% max

Residuals: 0.15% max

3003 aluminum coil is one of the most widely used insulation aluminum sheets recently. It is likely that it will gradually replace 1060 insulation aluminum sheet in the future, because 3003 insulation aluminum sheet has manganese element and good corrosion resistance, and it is much better than 1060 in terms of its service life.

3003 aluminum coil falls on three types based on thickness and surface treatment by aluminium coil manufacturers: 3003 mill finish aluminum coil, color coated coil aluminum 3003 and 3003 aluminum foil. Mill finish 3003 coil is mainly used to protect products against moisture. It can be used as packaging cover for cell phones, parts of fridges, air conditioners and cooling storage rooms, and air pipes etc. 3003 aluminum coated coil sheet is widely used for building industry, such as roofing and sidings, ceilings, corrugated sheets, good for insulation of heating and cooling. 3003 foil, from 0.015 to 0.2mm thick, is applied to electronic foil, honeycomb substrate, meal box materials and so on.

3003 aluminium alloy aluminum coil is beautiful and attractive. And the color does not fade in winds and rains. A great advantage of the 3003 alloy coil aluminium is that after the acid rain baptism, there will be no falling off or discoloration, especially in cities subject to rainwater. The density of aluminum is 2.71, much smaller than iron. Thus aluminium alloy rolls are lighter and more extensive in application. Last but not least, the price of 3003 aluminum is only half of that of iron piece of the same size, which makes it a more cost efficient material in many areas.

Nydia

Nydia

Sales Manager

Sales Manager